Illness among animals especially dogs can be significantly higher when many of them are boarded within close proximity, or kept within the same room or building. Airborne illnesses can easily be transmitted from one animal to another. Odors may cause issues when they migrate to other areas and affect staff and visitors.

Sanuvox UV systems are the ideal solution for destroying airborne viruses and bacteria, as well as reducing the concentration of unpleasant odors, such as ammonia produced by animals in kennels, shelters, pet stores and veterinarian clinics. Its proprietary system eradicates biological contaminants (bacteria, viruses, germs and allergens), and destroys chemicals and biological odors.

THE EQUIPMENT

Multiple application UV systems can be used for both stand-alone and duct-mount installations.

As stand-alone units, the P900 is equipped with an 80 cfm blower, the Sanuvair® S300 with a 300 cfm blower, and the Sanuvair® S1000 with a 1000 cfm blower. Sanuvair® S300 and S1000 also come with filters to capture particulates (pet hair, etc.). A dual zone UV-C/UV-V lamp is standard. An “adjustable” oxidizing lamp is available.

As an in-duct unit, the Quattro is installed parallel to the airflow and includes four UV-C/UV-V lamps, each with a one-inch section of oxidizing UV-V. Two of the lamp’s oxidizing sections are covered with removable foil, allowing for increased oxidation if necessary.

Typical installations:

OPERATING THE EQUIPMENT

Each unit treats the air through recirculation in two ways:

1. The Germicidal UV-C lamp portion destroys airborne biological contaminants (viruses, mold,

bacteria.)

2. The Oxidizing UV-V lamp portion reduces airborne chemical contaminants and VOCs through

photo-oxidation.

PROCESS ON BIOLOGICAL AND CHEMICAL CONTAMINANTS

1-ACTIVATION PHASE: H2O + O* –> OH* +OH*

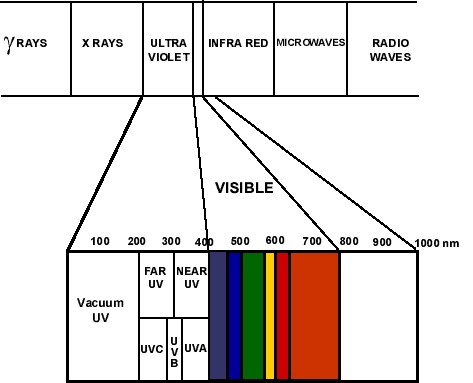

Ultraviolet photon energy (170-220nm) is emitted from a high-intensity source to decompose (break down) oxygen molecules into activated monoatomic oxygen. The rate of production or effectiveness of this process depends on the wavelength and intensity of its source.

2-REACTION PHASE: OH*+P –> POH

The activated oxygen atoms (O*) are then mixed in the airstream; the process will react with any compound containing carbon-hydrogen or sulfur, reducing them by successive oxidation to odorless and harmless by-products. If airborne contaminants are outnumbered by the activated oxygen atoms, then there will be formation of residual ozone (O3) which will occur following the oxidation of normal oxygen molecules (02).

3- NEUTRALISATION PHASE: (also germicidal) O3+UV(C) –> O2+O*: O+O –> O2

CHEMICAL DECOMPOSITION:

Ammonia NH3+OH* –> N2 + H2O

WHERE TO INSTALL

Many buildings and facilities can be equipped with either the stand-alone disinfection units or the in-duct unit, like kennels, pet boarding and animal shelters, laboratories, veterinarian centers, and zoos and pet stores.